0.5-0.9mm Color Steel Galvanzied Steel Rack Shelves Roll Forming Machine, Back Panel Roll Forming Machine

| |

ITEM |

SPECIFICATION |

| 1 |

Raw Material |

Coil material ( Color painted steel,galvanized sheet,brass strip)

|

| 2 |

Material Thinckness |

0.4-1.0mm |

| 3 |

Coil Material Width |

100mm to 200mm |

| 4 |

Capacity |

3-5m/min |

| 5 |

Products Length |

Any available |

| 6 |

Finished Product Dimension |

As per customers’ drawing |

| 7 |

Power |

380V/ 50Hz/ 15kw |

| 8 |

Temperature |

0-40℃ |

| 9 |

Humidity |

60-95% RH |

Shelf Back Panel Machine Components

|

|

|

|

|

Max 5T

Max coil:800mm

Hydraulic expansion and motorizied decoiling

|

Holes Punching & corner cut

|

We use hydraulic punching machine

Corner cut mould:2 sets ( left and right side can be adjustable manually)

Lateral holes punching mould: 1 set( position can be adjustable manually)

|

|

|

wall panel catilever structure

44 forming stations

7.5KW motor or Siemens brand

|

Hydraulic Cutting&bending mould combination

|

Cutting power:5.5kw

Mould material:Cr12.HRC58-62

|

|

|

|

|

|

PLC control system ,Siemens from German brand

Yaskawa inverter from Japan

|

|

|

Solenoid is made in China

|

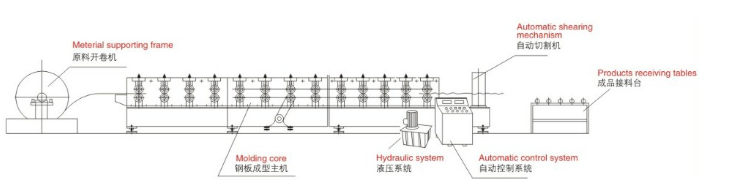

Working flow of Rack Shelf Machine

De-coiler—→Hydrauli -pre-cutting—→ Hydraulic punching notch—→Main roll forming machine—→Hydraulic cutting&Bending—→ Run out table

Shelf back panel Application

Shelf box panel is commonly used in the manufacturing of shelves for storage systems, such as warehouse racking and retail displays, convenience stores, grocery stores and supermarkets, liquor stores, pharmacy stores, sports nutrition and vitamin stores, hardware stores, discount stores, pet stores, party stores and more.

The panel can be customized in terms of size, thickness, and material composition to meet specific requirements.

Rack Shelf Machine Picture

1. The machine adopts PLC full-range intelligent control, and the automation program is high, safe and efficient.

2. The forming frame is welded using high strength channel steel. High strength and long service life.

3. The material of the roll shaft is 40Cr, and the hardness is HB280 after quenching and tempering treatment.

4. The material of the molding die is Cr12, quenching treatment, hardness: HRC 56-62 °C.

5. The transmission structure is chain transmission.

FAQ

1. Does one machine can only produce one size?

Not exactly, it depends on which profile the customer want to produce.

2. Do you have after-sales technical support?

Yes,we are happy to give advice and also have skilled technicians available to maintain the machine overseas to customers’ workshop if needed.

3. You are trading company or factory?

We are Manufacturer, and we export our machine by ourselves.

4. Do you provide customized?

Sure, we can design the machine according to the requirement and profile drawing you provide. Our engineers can offer the best professional solution to our worldwide clients.

5. How to visit your factory?

By high speed train from Shanghai to East Wuxi (Wuxi station), half an hour.

6. What's the warranty period?

18 months warranty period, starting from the date of the successful installation and commissioning of the equipments at the Buyer’s Installation site.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!